I received a caterpillar toy for a repairing.

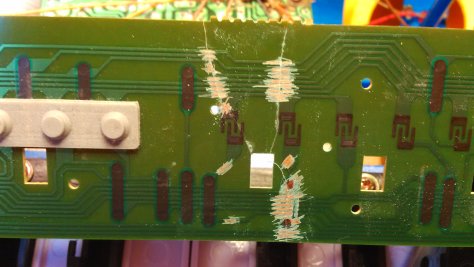

The metal slots holding up the front shaft keep getting stuck with the shaft’s cranking mechanism, and obviously stopped rotation. The other slot is clearly visible in this picture(red arrow), and also is the way I finally got it right. (Those short white plastic tubes.) At first I tried to make a sheet metal support inside of the metal support frame, but there was no room for that, shaft’s corners came in the way.

Here are the tubes, marked with red arrows. Plastic tubes don’t let the shaft move too much sideways and that way cranking mechanism can’t get in touch with the slots. It is not perfect, it still get stuck sometimes, but it is a way much better than before. I saw the owner’s test-drive and it went okay.

Wooden wheels came off by just pulling hard enough and that way I could just slide in the tubes.

I found those plastic tubes from my part collection of a torn apart devices. Oh, and I had to use a file on the corners of the shaft to make things smoother.

Black bar’s other end is connected to caterpillar’s rear end. The cranking mechanism makes the toy move like a real caterpillar. It is a quite clever invention, but execution is poor, tolerances are too big.

Toy was made by a good quality company, which make me kinda sad, they used to make good toys in the old days.. But on the other hand, one have to remember, this is the only one example of company’s many many products and maybe this was made on Monday.. 😉

Sail on!